M2M TECHNOLOGIES

We offer a range of industrial IoT devices, tools and plant automation solutions for the unique needs of your enterprise. Get connected with M2M.

Nexto Series is an advanced automation system capable of controlling, in a distributed and redundant way, complex industrial processes, machines and high performance production lines. Modern and fast, Nexto products are based on cutting edge technology.

Integrating functions present in Distributed Process Control Systems, Nexto products count on advanced features, such as hot swapping, CPU redundancy, I/O expansion module capacity and scalable architecture based on deterministic Ethernet, for all steps of an application’s life cycle. The series programmable controllers feature high flexibility, which enhances the development of the application, reducing engineering costs and commissioning in one and only control platform with integrated programming environment (IEC 61131-3).

Designed with high technology in safety and integrity for different types of applications, Nexto Safety solution was created with the goal to minimize the probability of dangerous failures on the development of projects and products manufacturing. Produced with the latest technology in safety, the products of this line hold the ISO 13849-1 (Cat. 4 Ple.) certification, as well as IEC 61508 and IEC 62061 (up to SIL 3 level).

Nexto Safety line enables the use of conventional and safety equipment in the same backplanes and communication networks. The feature enables the implementation of a simplified project, with backplanes, power supply, network interface and integrated programming tool, in addition to securing data exchange between the Safety CPU and the conventional in a safe way. The integrity of data is ensured with the use of a safe protocol, such as PROFIsafe, which is the standard protocol used by Altus safety solution that reduces the probability of failures on data transmission from a controller and a safety I/O. Extremely versatile, the protocol allows the creation of applications with mixed mesh.

About Us

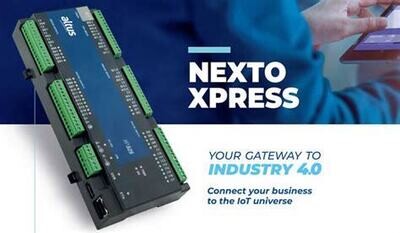

With the advent of Internet of Things and Industry 4.0, process intelligence requires an increasing amount of Machine to Machine (M2M) data exchange. There is an ever growing demand for interoperability- the ability to exchange data with cloud-based systems- and user-friendly local configuration and maintenance. The reliance on a singular manufacturer solution in this ever-connected world is no longer an option. Operational data is available from a wide variety devices from manufacturers in every segment. We provide a suite of tools and products enabling isolated sets of units and devices to be a cohesive part of the overall automation system and enterprise solution (and even supply chain).